- Cleans one turbine in approximately 20 seconds

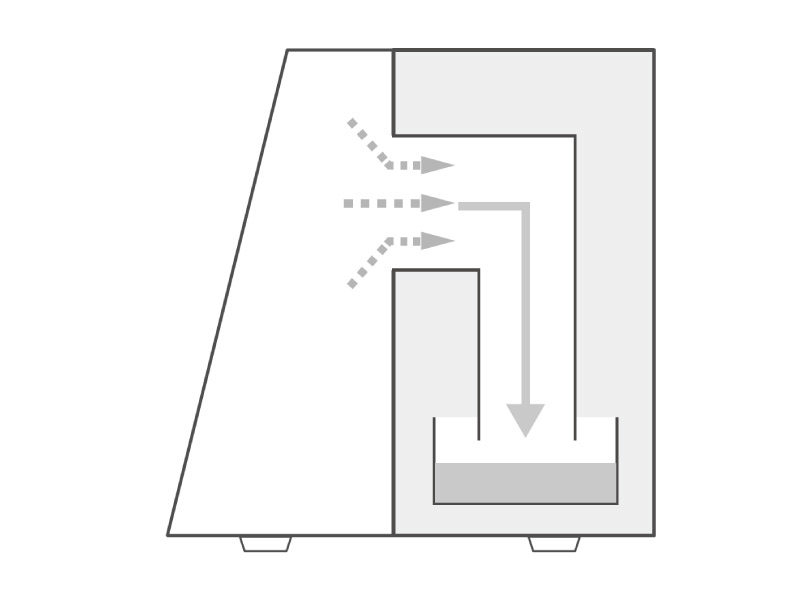

- Oil usage amount is reduced to 1/4

- Faster maintenance with excellent cost savings

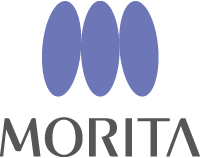

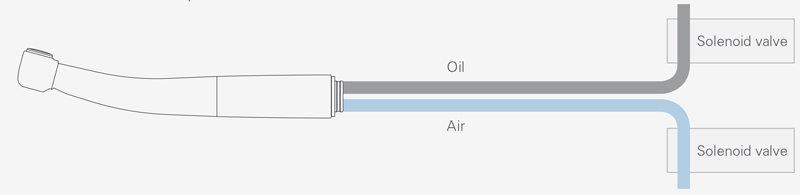

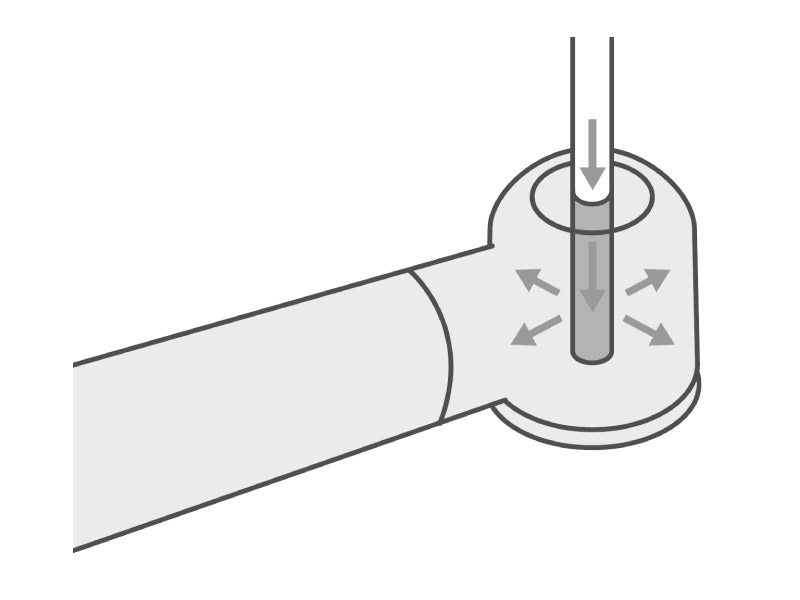

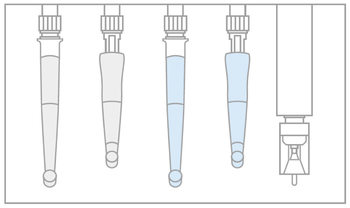

Since the air-blow system can remove residual water completely using clean air, the efficiency of lubrication is enhanced with oil usage only 1/4 of that compared to manual lubrication. Daily maintenance cost is therefore reduced. In addition, the system can remove surplus oil effectively, allowing maintenance in a short time1.

Handpiece and spray compatibility

Example: One turbine and contra angle by Morita and one turbine and contra angle by another manufacturer.

By replacing the coupling, Lubrina 2 facilitates the maintenance of Tri Auto ZX2 and DentaPort contraangles, air driven handpieces (ISO 9168/Type 3 joint) as well as all contra-angles and straight handpieces (ISO 3964/E-Type joint). Lubrina is compatible with 4-hole, 5-hole, and 6-pin connections. With its dual lubrication system, one or two different brands of spray may be used in the same cycle. Several brands of spray are compatible by using an optional spray holder adapter.

1 Comparison with the long mode of our previous Lubrina

2Approximately 40 seconds for contra-angle handpiece